High borosilicate glass (also known as hard glass) is made by melting glass through heating in the interior of the glass, using the conductive property of glass at high temperature, and by advanced production technology. It is a kind of special glass material with low expansion rate, high temperature resistance, high strength, high hardness, high transmittance and high chemical stability. Because of its excellent performance, it is widely used in solar energy, chemical industry, pharmaceutical packaging, electric light source, handicrafts and other industries.

Common glass in the market are soda-lime glass (ordinary glass), tempered glass and high borosilicate heat-resistant glass.

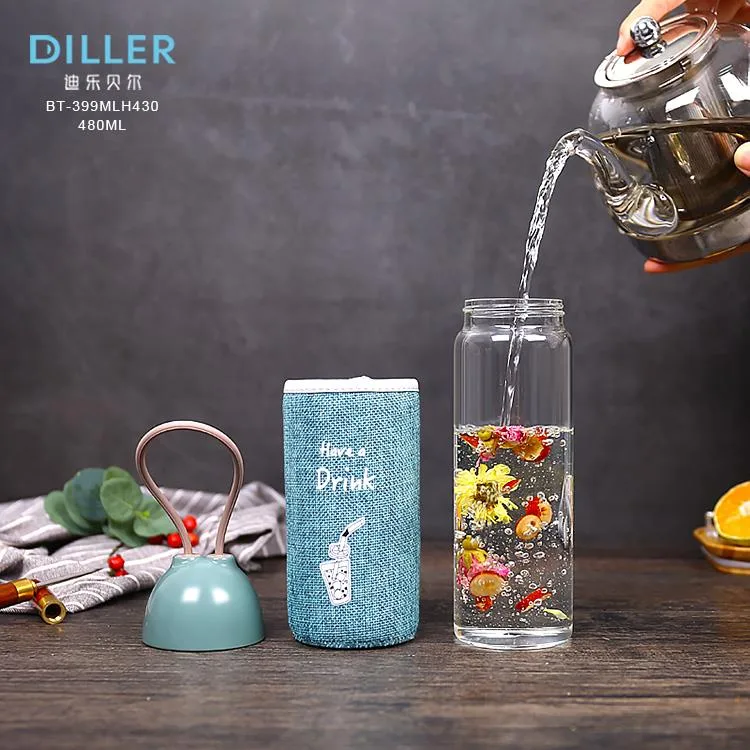

High borosilicate heat-resistant glass can withstand the instantaneous temperature difference of about 150℃. It is safe to serve hot and cold drinks. The main processes are manual blowing and semi-automatic assembly line.

Ordinary glass can only withstand the temperature difference of 75℃ in an instant. It is mainly used in cold beer, mainly in pressing process and iron pipe blowing process.

Thicker tempered glass is generally not used in cups. The specific methods for distinguishing high silicon boron are as follows:

1. The cup with thicker bottom is not made of high borosilicate glass.

2. Double glasses, most of which are made of high borosilicate heat-resistant glass;

3. The glass with handle is light and thin. The glass thickness of 2 mm is usually high borosilicate glass.

4. The water cups used in high borosilicate daily are mainly manually blown. The raw materials are mainly high borosilicate glass tubes, which are fired and softened at high temperature, then placed in the mould for rotary or fixed blown moulds.